HBL9160D Film For Encapsulating Solar Cells

|

HBL9160D HBL9160Dis developed by Nanjing Hongbaoli New Material Co., Ltd. as fast cure cross-linking EVA encapsulation film for solar panel.

HBL9160Dfilm is based on the raw material of the solar type ethylene - vinyl acetate (EVA resin) by adding various additives with excellent cross-linking properties of EVA film by casting method. |

|

Types and specifications of products |

| Item |

HBL9160D-709 |

HBL9160D-705 |

HBL9160D-709P |

HBL9160D-705P |

| Model description |

Conventional |

High permeability |

Conventional anti PID |

High penetration PID |

| Thickness/mm |

0.2-0.8 |

| Width/mm |

200-2000 |

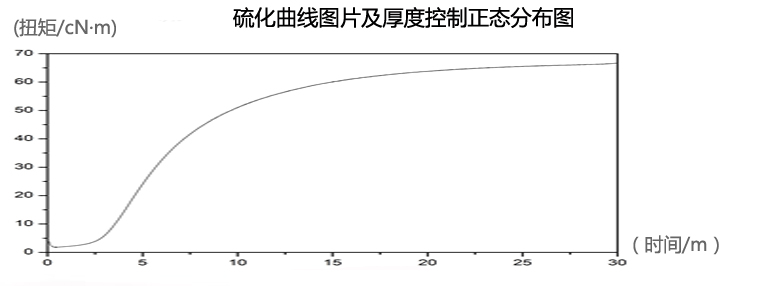

1、Laminate:Fast laminate processing,high efficiency,good dimensional stability during laminations,bubble and void-free lamination;

2Adhesive: High adhesive strength with glass and backsheet, and maintain good adhesive property after aging;

3、High light transmission rate and long lasting

4、Excellent reliability and weather resistance: resistance to heat humidity、wet frozen and ultraviolet ray durability;

5、Low Shrinkage: avoid some possible problems such as solar cells moving, overlapping, broken and the lack of colloid phenomena;

|

Technology, Equipment and Quality Control |

|

1、ully closed and automatic feeding systems;

2、Imported automatic EVA film production line:

1) 15 million square meter annual capacity by single production line

2) Die head bolts automatic control system

3) Low tension no stop winding roll cut off

3、The controlled formula is derived from foreign advanced techniques;

4、No pollution management and control on materials and process.

5、Adcanced and perfect equipments for R&D,production and experiment; |

| Item |

Unit |

Test Mehod |

HBL9160D-709 |

HBL9160D-705 |

| VA Content |

wt.% |

TGA |

28.33 |

28.33 |

| Tensile Strength |

MPa |

GB/T 1040 |

≥15 |

≥15 |

| Elongation at Break |

% |

GB/T 2410 |

≥400 |

400 |

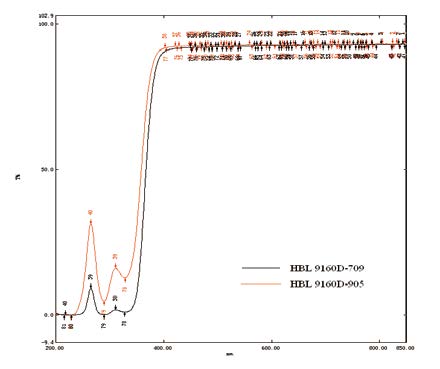

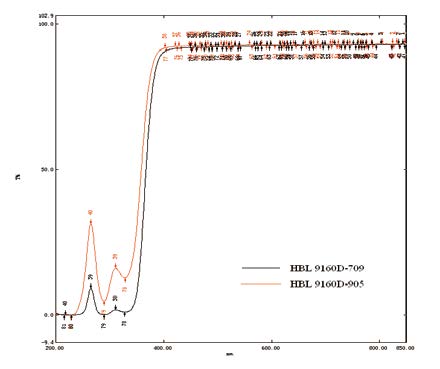

| Optical Transmission(380nm-850nm) |

% |

HBL Method |

≥90.5 |

90.5 |

| UV-Cutoff Wavelength |

nm |

ISO 489 |

360 |

310 |

| Refractive Index |

/ |

GB/T 1034 |

1.49 |

1.49 |

| Water Absorption |

% |

GB/T 2790 |

<0.1 |

<0.1 |

|

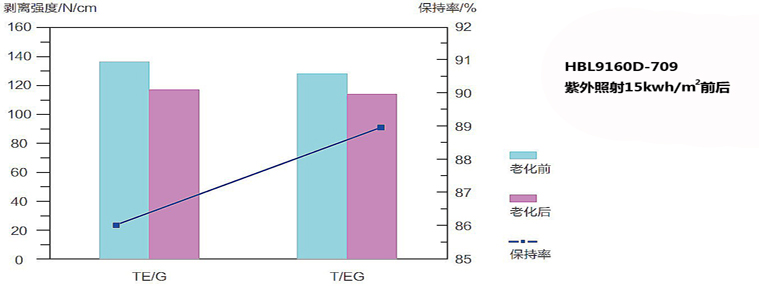

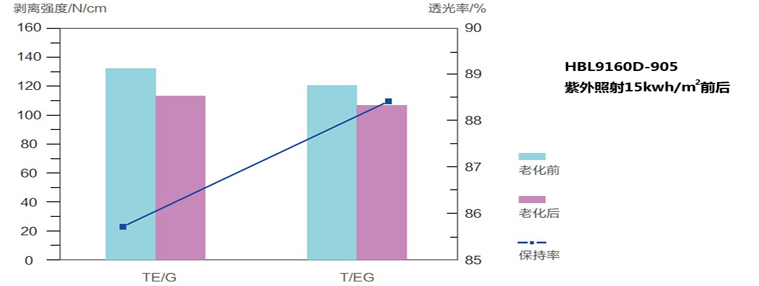

Peeling Strength

(145℃,15min) |

EVA/Glass |

N/cm |

HBL Method |

≥60 |

≥60 |

| EVA/Backsheet |

HBL Method |

≥50 |

≥50 |

|

Heat Shrinkage

(120℃,3min) |

MD |

% |

GIE 1976 |

≤3 |

≤3 |

| TD |

GB/T 2410 |

≤3 |

≤3 |

|

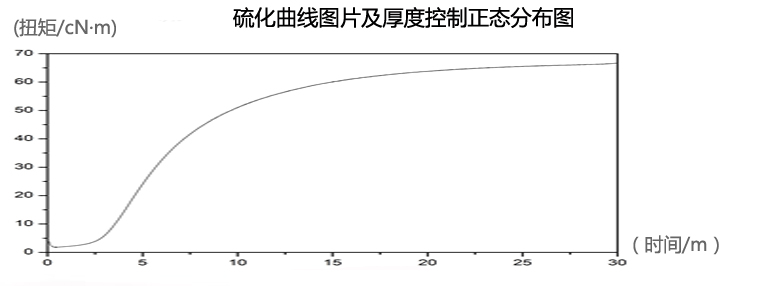

Cross-linking Degree

(145℃,15min) |

% |

GB/T 2790 |

≥75 |

≥75 |

|

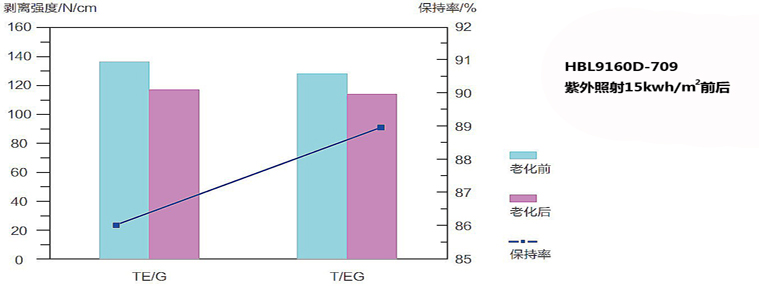

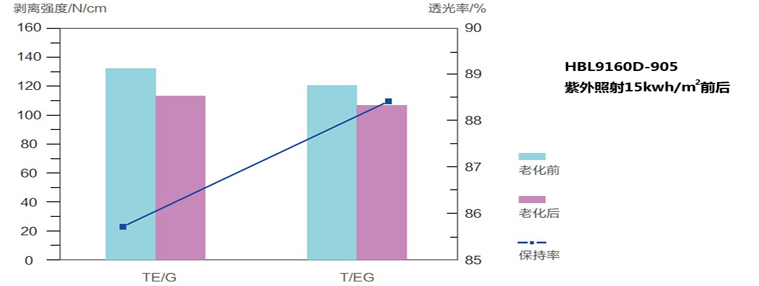

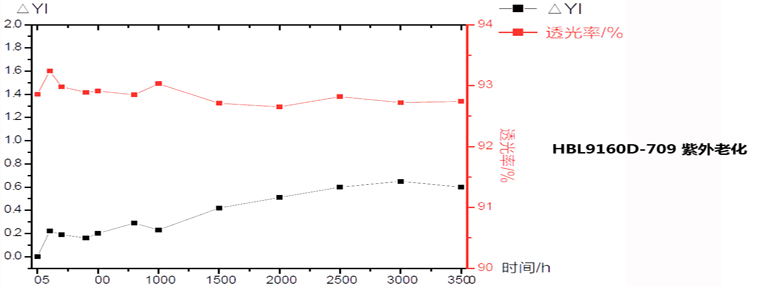

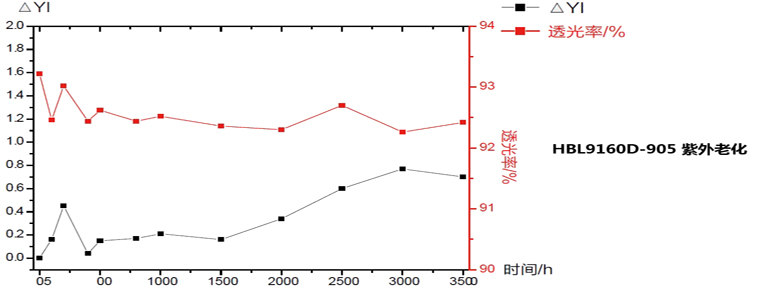

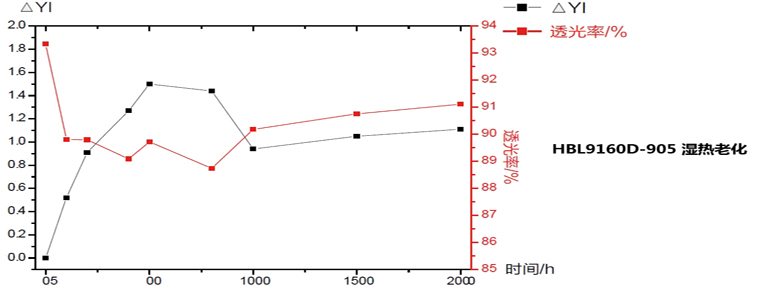

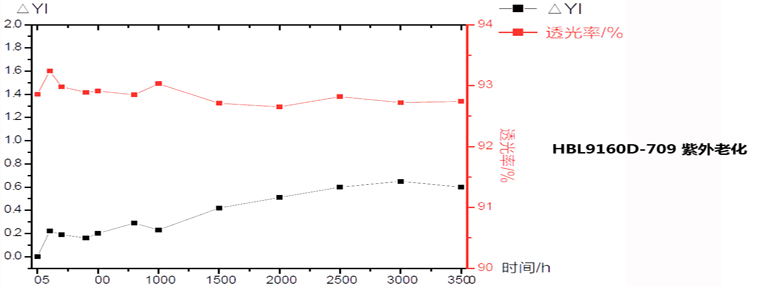

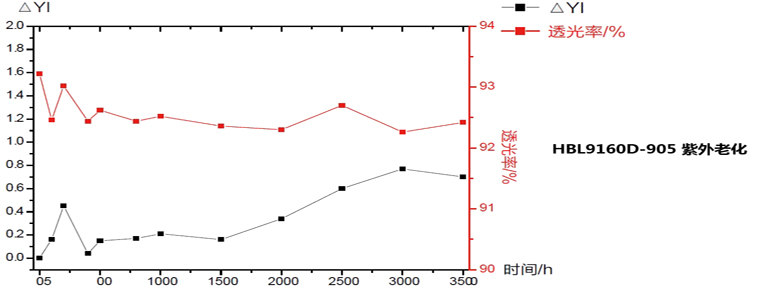

UV Light Resistance

(UVA,60℃,15kwh/m²)

|

黄变指数 |

△YI |

CIE 1976 |

≤3 |

≤4 |

| 透光率 |

% |

GB/T 2410

|

≥85 |

≥85 |

|

粘结强度保持

(与玻璃) |

% |

GB/T 2790

|

≥80 |

≥80 |

|

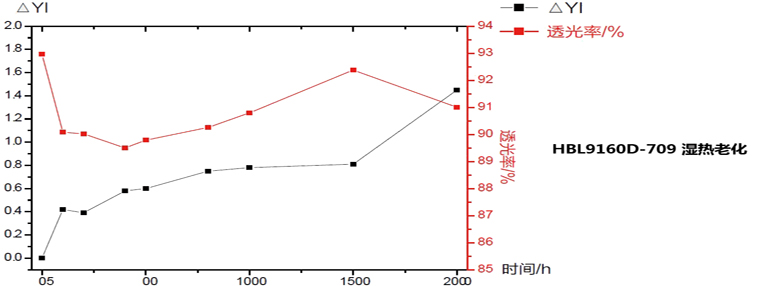

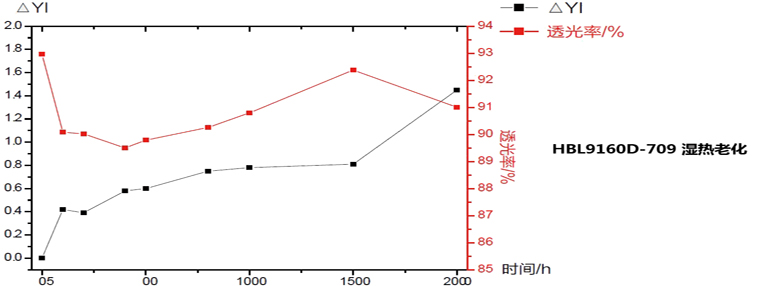

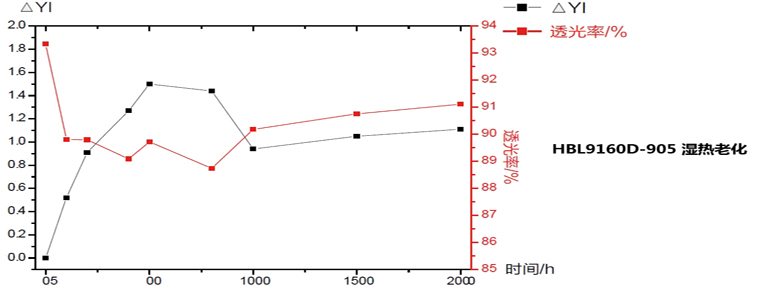

Damp Heat Resistance

(85℃,85%RH,1000h |

黄变指数 |

△YI |

CIE 1976 |

≤3 |

≤4 |

| 透光率 |

% |

GB/T 2410 |

≥85 |

≥85 |

| 粘结强度保持

(与玻璃) |

% |

GB/T 2790

|

≥80 |

≥80 |

| Volume Resistivity |

Ω·cm |

GB/T 1410

|

≥1.1*1013 |

≥1.1*1013 |

| ielectric Strength |

KV/mm |

GB/T 1408.1 |

≥19 |

≥19 |

|

1) Core for roll is paper roll, Inner diameter:76.5mm±0.1mm,Wall thickness:8mm±0.05mm,Core width: Film order size +5mm;

2) Each roll is packed with PE film,and inserted the plastic core holder into the two sides of the core,then put into carbon box;

3) Label is attached on each box,the label shows the trade name、lot numbers、dimensions、quantity;

4) 16 Rolls per pallets;

5) Pallets will be used according to the product size and quantity;

6) Fastened by PP band and the outside is fixed by stretch film;

|

|

Wrranty period and storage requirements |

|

1. Warranty Period:

The product is guaranteed for 6 months from the production date in the unopened state, 3 months suggested to use up;

2. Storage Method:

1) EVA film storage environment requirements(Relative humidity below 60%, the temperature at 0 ℃ to 30 ℃ within)

2) Keep the original packaging tightly packed, protected from light;

3) EVA films should be kept in the warehouse without oil, water, organic solvents or other chemicals; |

|

Perfect after-sales service system

Efficient and accurate consignment and delivery tracking support

xcellent technical consultant for product application

|

|

TUV Certification and CGC-SOLAR

The 10th China Quality Award

National Enterprise of ‘Keeping Promise & Honoring Contracts’

Postdoctoral Programme

National Quality Award, Encouragement Award

|

|

Company Profile

Company Profile  Video

Video  Culture

Culture  Awards

Awards  Polyurethane insulation panel

Polyurethane insulation panel  Polyurethane insulation decorative panel

Polyurethane insulation decorative panel  EVA Film

EVA Film